CONDRA CRANES FOR PLATFREE PGM

Condra has delivered electric hoists, two overhead cranes and a number of chain blocks to Platreef Mine, part of the Platreef PGM project near Mokopane in Limpopo Province, South Africa.

The lifting equipment will be used for machinery maintenance work at various points across the mine site.

Under development since 2020 by Ivanplats (Canada-based Ivanhoe Mines’ South African subsidiary), Platreef comprises two vertical production shafts, a ventilation shaft, a concentrator and associated supporting infrastructure.

Mine production, scheduled to begin this year, will tap a 26-metre-thick flat ore body extending over several kilometres to deliver 12 megatons per annum over a lifespan of three decades, positioning Platreef among the largest platinum group metals (PGM) mines in the world. Annual yield is expected to exceed one million troy ounces of palladium, platinum, rhodium and gold, plus useful quantities of nickel and copper.

The mine’s overhead cranes and hoists are currently being installed. Condra was selected to manufacture the machines by consulting engineers Dowding Reynard and Associates.

The electric cranes, of single-girder and double-girder overhead configuration, are for the filter building and the plant workshop, one of the machines having dust-ignition-proof rating to ATEX Zone 21/22 standard. Lifting capacity of the single-girder crane is five tons, while the double-girder crane will lift loads up to ten tons. Control of both cranes will be by radio remote with manual pendant back-up.

Two hoists accompanied delivery of the cranes: a short-headroom hoist for the tailings filter, and a K-Series hoist for the mill feed conveyor. Both will be used for maintenance work.

Mining applications account for more than half of Condra’s orders from customers across sub-Saharan Africa and the Americas, met by production at factories in Johannesburg and Cape Town. The European market is serviced by a subsidiary company in Bulgaria.

Condra boasts a manufacturing pedigree going back more than 50 years, claiming the highest local content of any African overhead crane supplier south of the Sahara Desert. Local content allows the company to deliver overhead cranes with the lowest possible lifetime cost, supported by a comprehensive back-up service and rapid spare parts delivery.

All Condra products are manufactured to ISO 9000 standard, with the full range covering capacities from 250 kg to 500 tons. A fully automated option is offered on all machines.

The company’s success in securing significant orders against determined competition seems set to continue.

The lifting equipment will be used for machinery maintenance work at various points across the mine site.

Under development since 2020 by Ivanplats (Canada-based Ivanhoe Mines’ South African subsidiary), Platreef comprises two vertical production shafts, a ventilation shaft, a concentrator and associated supporting infrastructure.

Mine production, scheduled to begin this year, will tap a 26-metre-thick flat ore body extending over several kilometres to deliver 12 megatons per annum over a lifespan of three decades, positioning Platreef among the largest platinum group metals (PGM) mines in the world. Annual yield is expected to exceed one million troy ounces of palladium, platinum, rhodium and gold, plus useful quantities of nickel and copper.

The mine’s overhead cranes and hoists are currently being installed. Condra was selected to manufacture the machines by consulting engineers Dowding Reynard and Associates.

The electric cranes, of single-girder and double-girder overhead configuration, are for the filter building and the plant workshop, one of the machines having dust-ignition-proof rating to ATEX Zone 21/22 standard. Lifting capacity of the single-girder crane is five tons, while the double-girder crane will lift loads up to ten tons. Control of both cranes will be by radio remote with manual pendant back-up.

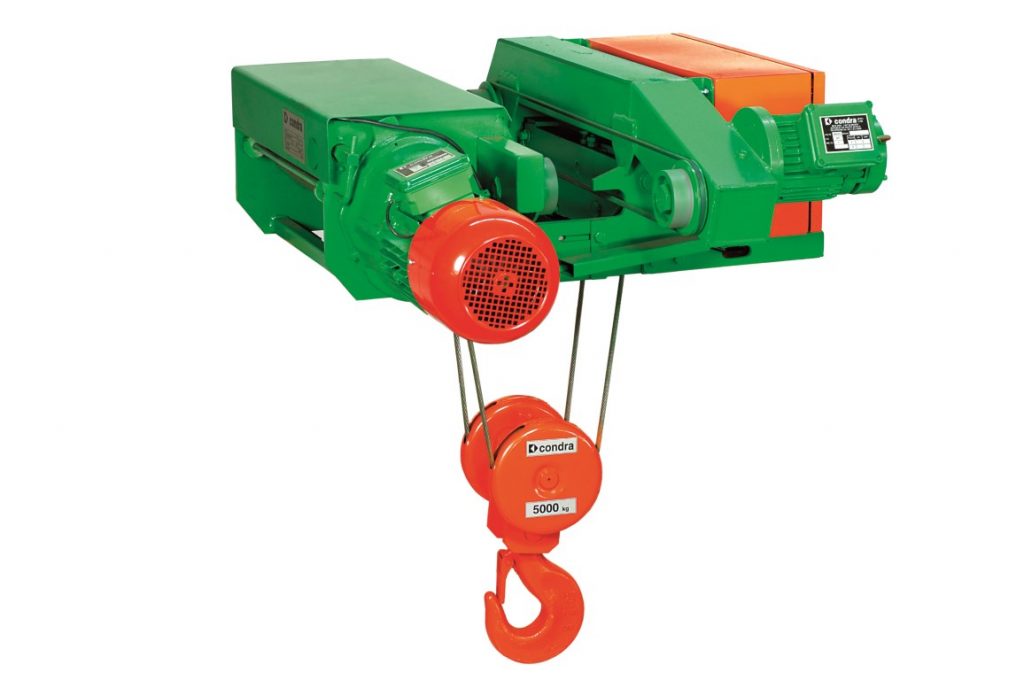

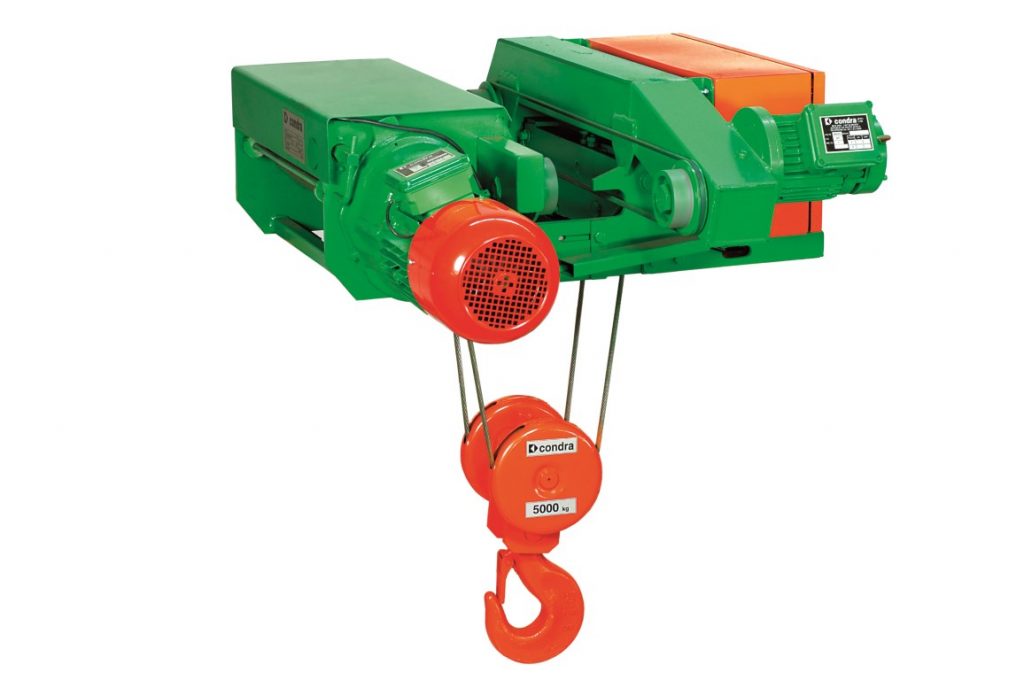

Two hoists accompanied delivery of the cranes: a short-headroom hoist for the tailings filter, and a K-Series hoist for the mill feed conveyor. Both will be used for maintenance work.

Condra K-Series hoist

Mining applications account for more than half of Condra’s orders from customers across sub-Saharan Africa and the Americas, met by production at factories in Johannesburg and Cape Town. The European market is serviced by a subsidiary company in Bulgaria.

Condra boasts a manufacturing pedigree going back more than 50 years, claiming the highest local content of any African overhead crane supplier south of the Sahara Desert. Local content allows the company to deliver overhead cranes with the lowest possible lifetime cost, supported by a comprehensive back-up service and rapid spare parts delivery.

All Condra products are manufactured to ISO 9000 standard, with the full range covering capacities from 250 kg to 500 tons. A fully automated option is offered on all machines.

The company’s success in securing significant orders against determined competition seems set to continue.

Condra short-headroom hoist